Increased beer filling speed for higher productivity: Comac Research & Development’s Fast Filling Project

Since the company was founded in 1990, brewing has been Comac’s core business: over the decades, the company’s ability to adapt to market trends and its capacity to develop innovative solutions have made working with companies of all sizes possible, from craft breweries to large international players in the field.

These results have been achieved, and continue to be achieved, also due to Comac R&D department, which works every day to offer customers increasingly high-performance systems suited to their specific requirements.

This desire has also led to the department’s most recent project, which has completed the preliminary study phase: Fast Filling, designed to increase the filling speed – and therefore the productivity – of all our filling machines.

Project overview

The aim of the Fast Filling project is to investigate and implement improvements (both mechanical and software) on filling machines and systems to maximize the time needed to perform a complete filling cycle.

For this project, the standard stainless-steel keg was taken as a reference.

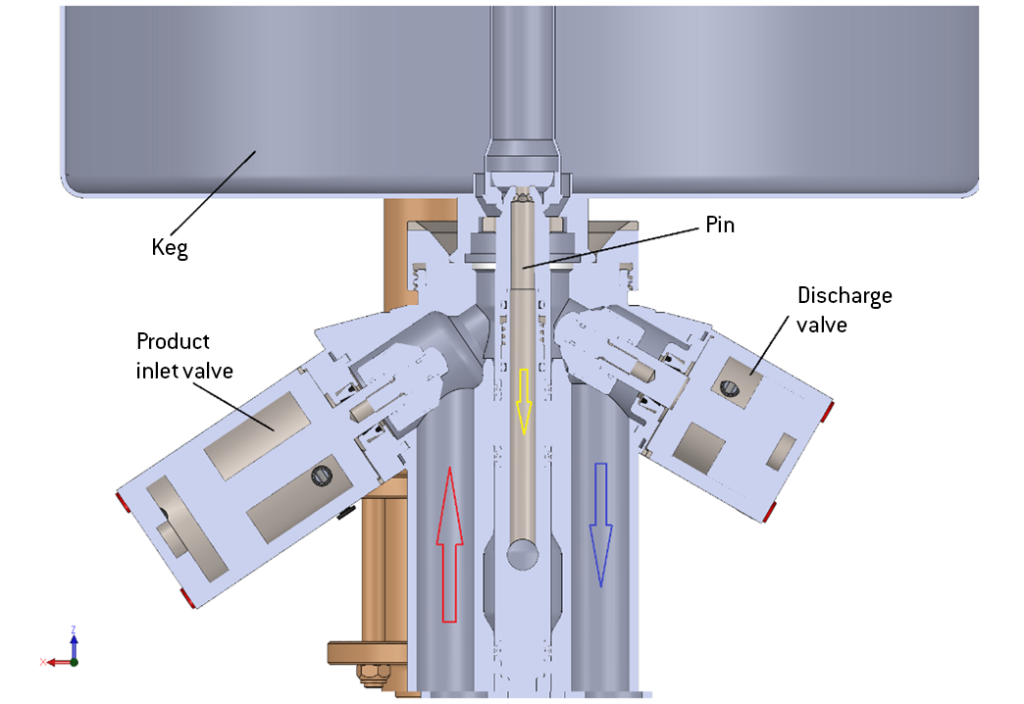

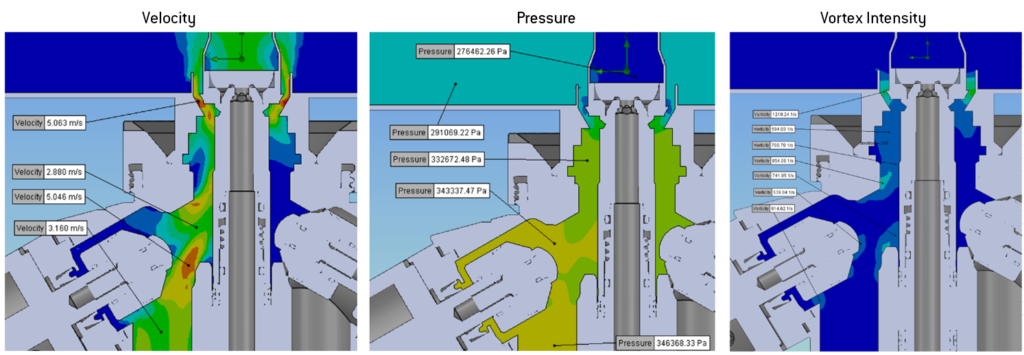

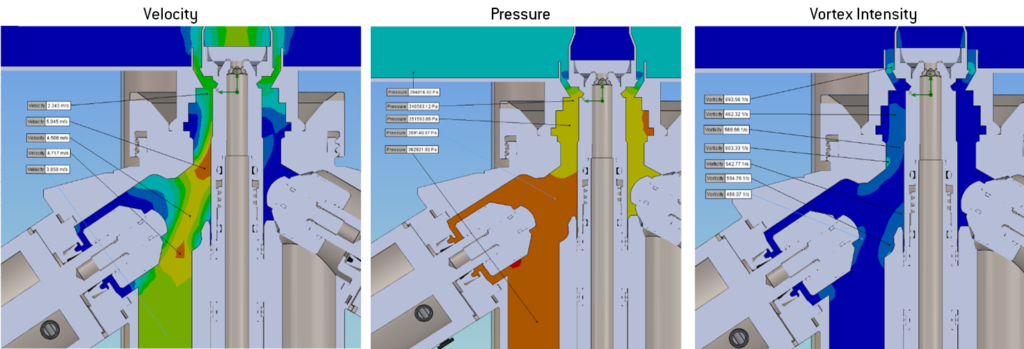

The work was based on Computational Fluid Dynamics (CFD) simulations and its first phase has seen the assessment of the “actual state”, by observing the physical behaviour of piping, valves and heads currently used in our filling machines.

The actual state, from a fluid-dynamic point of view, is therefore the initial point, but also the last point of the project. All the modifications, in fact, have been implemented taking the current condition as a reference.

The parameters considered when defining the changes applied to the model are:

- Velocity gradient

- Pressure drop

- Vortex intensity

Simulation results in ‘actual state’

Problem approach

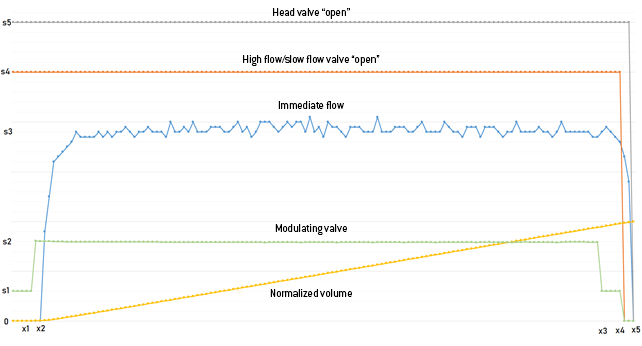

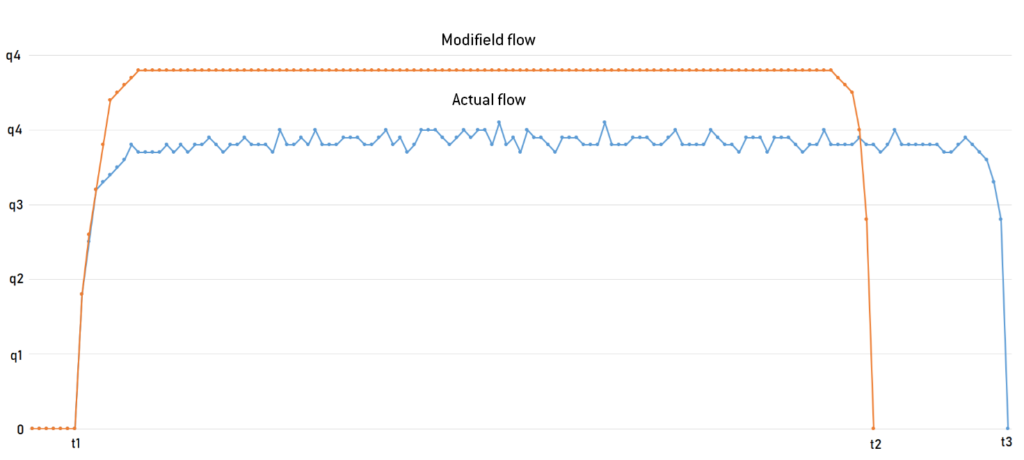

The actual behaviour of a Comac Filler during a filling cycle is shown below.

Complete filling cycle – actual state

The blue curve shows the immediate flow, i.e. the number of litres (flow rate) of product injected in the keg during filling. The initial phase of the cycle is marked out by an almost zero flow, since the modulating CO2 discharge valve is only opened at s1. Modulating the valve at s2 generates a transient that brings the system to steady state.

The final filling step involves the partial closing of the modulating valve (which is set back to s1) resulting in a slowing of the flow. The last step foresees the total closure of the modulating valve and the simultaneous closure of the high flow with consequent transition to slow flow. This final step, in particular, is necessary to guarantee the accuracy of the total volume fed into the keg before the product inlet valve (head) is completely closed.

This data was the fundamental basis for all the modifications to be made, with the aim of reducing the filling time as much as possible, in line with the possibility of foam formation.

Results

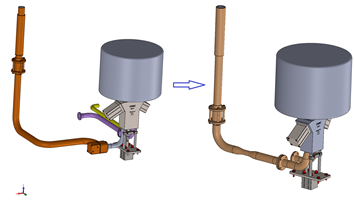

Per raggiungere l’obiettivo sono state progettate diverse modifiche:

- simplification of the piping route

- replacement of the high/low flow valve with a more efficient one

- translation and rotation of the closing cylinder

The modifications implemented have made significant improvements to the fluid-dynamic parameters.

Specifically, the simplification of the piping path and the replacement of the high/low flow valve with a better performing one have reduced pressure losses, while the translation and rotation of the closing cylinder have helped to reduce the velocity gradient and turbulence inside the cylinder head.

Simulation results in “modified model”

The improved filling cycle (see figure below) was therefore determined based on an optimization calculation, taking into account:

- the acceleration profile of the filling curve in the initial transient was kept constant.

- the steady-state flow rate was increased in accordance with the reference fluid-dynamic parameters (i.e. the current ones).

- the decrease in flow, of course, considers the total capacity of the keg.

Following the changes, all the indicators examined met the thresholds defined at the outset.

Conclusions

Following this study phase, the Fast Filling project is now ready for a further step: Comac R&D department will soon test the modifications, using a test bench.

If the tests confirm the expected progress, the modifications will immediately be implemented to all Comac filling machines, allowing a productivity increase (kegs/hour) by 18%.

The advantages for customers will therefore be tangible: Comac machines will be even faster and more efficient, perfect for the requirements of whoever is looking for a system that combines high productivity and maximum quality of the finished product.