Co.Mac. launches its new PALinspect AI – A revolution in pallet inspection

Inspecting pallet integrity is one of the most complex challenges in corporate logistics. A damaged pallet isn’t just a risk to the products it carries but can also compromise the timing and process of end-line operations. With the launch of its new PALinspect AI, Co.Mac. brings its expertise to the field. Find out how!

Technology serving safety and efficiency

Technology serving safety and efficiency

The new PALinspect AI by Co.Mac. is driven by a clear vision: ensuring that every pallet in circulation meets the highest safety and quality standards.

How does it work?

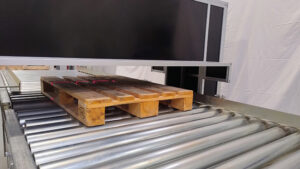

After a quick cleaning process to remove any debris (such as cellophane or separator sheets), the pallet undergoes a 3D scanning system. Due to advanced sensors such as cameras and profilometers, the machine detects even minor defects, like 8mm irregularities or 10mm holes, providing a precise structural integrity analysis.

Each scan generates a clear and detailed report, accessible through a user-friendly multilingual interface that allows operators to quickly address any damaged pallets. This automated system is designed to process up to 300 pallets per hour, ensuring continuous and optimized operational flow.

The result? A significant saving in time and resources, along with reduced risks related to transportation and storage.

Find out more about how our PALinspect AI works!

The perfect ally for workplace safety

Workplace safety is an absolute priority for every modern company. Damaged or defective pallets can pose real risks, leading to accidents during handling or transportation.

With PALinspect AI, Co.Mac. offers a solution to identify potential defects and help prevent such risks.

Identifying structural defects in advance means:

- Protecting workers from potential injuries

- Minimizing the risk of product damage

- Ensuring a smooth and seamless supply chain

This level of control not only enhances operational conditions but also demonstrates a commitment to detail and responsibility toward customers and employees.

Sustainability and innovation: our winning combination

In an era where sustainability is at the heart of corporate strategies, the PALinspect AI stands out as a forward-looking solution.

Identifying and isolating damaged pallets not only ensures safety and efficiency but also helps reduce waste. Non-compliant pallets can be repaired or recycled, limiting the need for new material production and significantly reducing environmental impact.

This sustainable approach translates into tangible advantages:

- Cost savings for the company

- A concrete contribution to reducing CO₂ emissions

With the new PALinspect AI, Co.Mac. proves that technological innovation and environmental responsibility can go hand in hand, offering a solution that not only meets operational needs but also supports greener and more responsible logistics.

Discover the full potential of our PALinspect AI!