Automatic bottle filler: the Comac models

Comac automatic bottle fillers offer numerous advantages in terms of both product quality and the customer’s brand image. These are our models.

Why choose a Comac automated bottle filling machine? This article will provide an overview of the best available models, and all their relative advantages in terms of quality, sustainability, and brand image.

Comac automatic bottle filler models

Comac offers a series of extremely efficient and highly technological automatic bottle filler models, designed to handle both standard and special-shaped glass bottles, based on the customers’ various needs.

A wide range of beverages can be handled, including:

- water, thanks to the use of a water bottling plant;

- beer

- wine

- alcoholic beverages

- non-alcoholic beverages

Based on production capacity, these automatic beverage filling machines are capable of bottling:

- up to 6,000 bottles/hour

- over 6,000 bottles/hour

Let’s take a closer look at some of the models, namely:

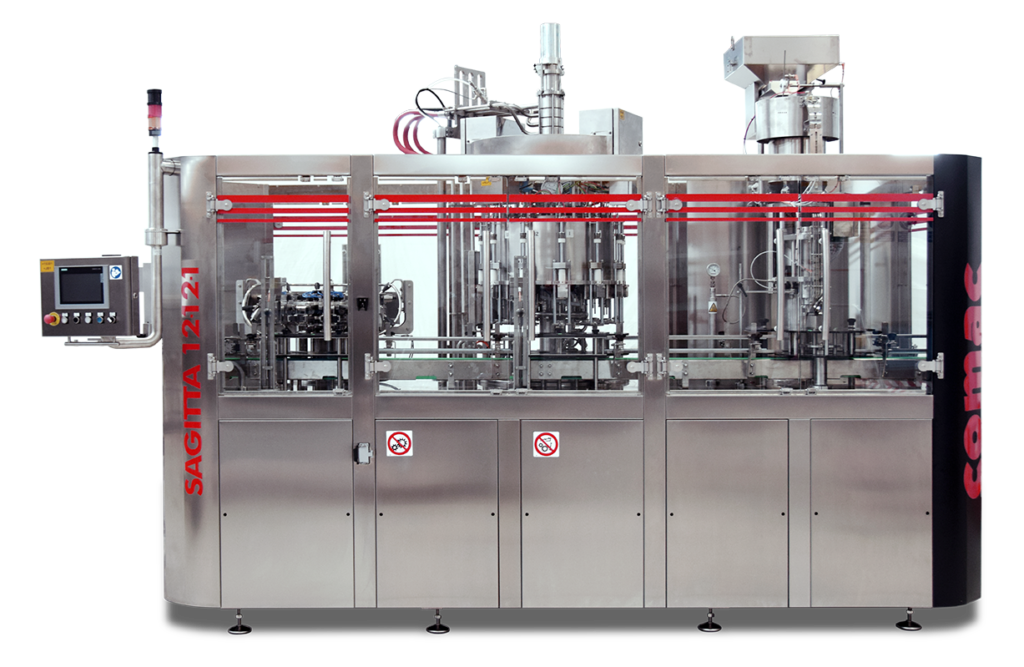

Sagitta 12-12-1 P

The Sagitta 12-12-1 P automatic bottle filler is an isobaric monoblock model capable of processing up to 3,000 bottles/hour. The machine features electro-pneumatic filling valves, and is an ideal solution for low/medium capacity lines.

Thanks to its back-pressure filling technology, this filling machine is perfect for bottling both carbonated and non-carbonated beverages.

The Sagitta 20-20-3 P

The Sagitta 20-20-3 P is an isobaric automatic bottle filler with a capacity of 6,000 bottles per hour.Like the previous one, this model also features electro-pneumatic filling valves, and perfectly meets all the bottle filling process parameters, including:

- flushing with CO2 or inert gas;

- vacuum execution in bottle;

- pressurization;

- filling;

- decompression

Special modifications and configurations can also be provided, based on the customer’s requirements.

With regard to the high production capacity models, or rather those capable of handling over 6,000 bottles per hour, these are manufactured in collaboration with CFT group.

Master RS Glass/PET

The Master RS Glass/PET automatic bottle filler is the model that offers the greatest production capacity (up to 80,000 bottles/hour). It can be furnished with electro-pneumatic valves for filling glass bottles, or with electronic valves controlled by magnetic flow meters for filling PET bottles.

Due to its back-pressure filling technology, this model is suitable for filling glass and PET bottles with both carbonated and non-carbonated beverages.

The Master RS Glass/PET also guarantees excellent performance in terms of:

- filling accuracy;

- control of oxygen content.

Find your automatic bottle filler

All the advantages of a Comac automated bottle filling machine

As previously mentioned, there are several advantages in choosing a Comac automatic bottle filler, not only because they guarantee excellent product quality (glass won’t release any undesired substances into the beverage), but also because of their sustainability.

Glass bottles can be reused

By choosing an automatic bottle filler, you’ll have the opportunity to take part in the circular economy process and help improve the well-being of the planet.

In fact, “packaging” glass, like that used for bottles, is renowned for being one of the prevailing most sustainable materials, as it is infinitely and 100% recyclable, and won’t alter the quality of the product after reuse, unlike plastic which entails a more complex disposal process.

Finally, many countries around the world have established “deposit” programs to encourage consumers to return empty bottles to producers. In so doing, the use of glass initiates a virtuous circle of sustainability, leaving consumers with fewer containers to dispose of and manage, and providing producers with a greater amount of recyclable material.

Using glass bottles improves the brand’s image

Beverage companies that choose to use glass bottles often find that this decision leads to a more positive brand image. In fact, this choice tends to draw the attention of those who are highly aware of material sustainability issues, as well as those in search of more sophisticated beverages.

What does this mean for you? Increased popularity, sales, and profits.

It’s time for you to take this step too, and choose Comac to improve every aspect of your production.