- for productions from 3,000 to 12,000 cans/hour

- for production over 12,000 cans/hour up to 70,000 cans/hour in collaboration with the CFT Group

The thirty years of technical expertise, the high technology and the quality of raw materials ensure reliability and optimum yields of the plants, designed to simplify and speed up the change over procedures.

Comac can lines are designed to process any kind of liquid beverage: water, juices, soft drinks, alcoholic beverages and beer. Beer canning is by far one of our major focus, as we supply many breweries all around the world with customized and highly specialized plants and ancillary machines.

Automatic canning machines

All our can lines are composed by automatic canning machines. These fillers are able to guarantee high productions, actually they can fill a great number of cans per hour of any format (aluminum and tinplate) according to the customer’s requirements.

In order to provide a better and more versatile service, Comac offers also a series of automatic ancillary machines for use in conjunction with filling lines. These include:

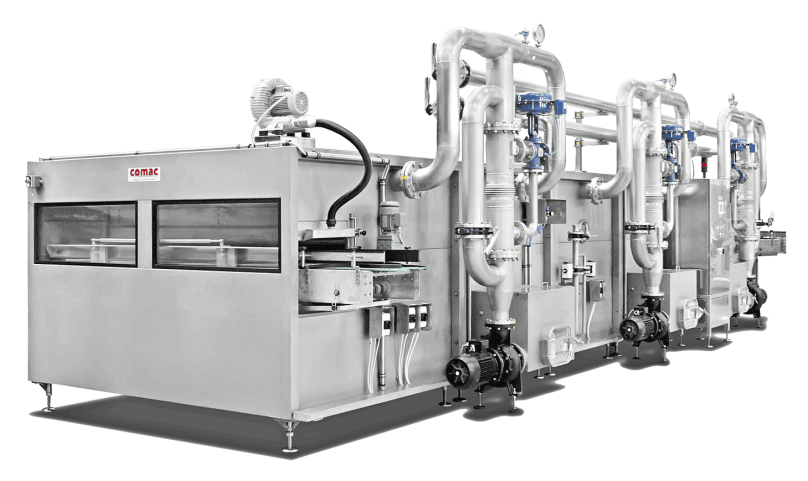

- Pasteurizer tunnel: used to pasteurize the product already packaged in cans;

- Cooling/heating tunnel: designed to bring the previously packaged cold or hot product to room temperature;

- Saturation unit: used for the carbonation of the product;

- Premix unit: used to create carbonated beverages through deaeration of water, addition of syrup and carbonation in order to obtain the finished carbonated product.