From the cleaning to the capping, Comac realizes safe and reliable bottling equipment, able to adapt to the size of your company guaranteeing the automatic filling of bottles of any type.

Bottling equipment includes a series of machines or plants realized to process the filling of bottles in beverage industries. It does not matter what size your business is: the bottling process always requires some necessary steps, each of them with a specific machine to perform it.

So, what bottle equipment do you need? It depends on many factors, including the space available, the capacity and number of bottles you want to fill, as well as the type of drink you need to bottle. Comac’s bottling equipment is easy to use and guarantees maximum reliability without the need for frequent maintenance.

Here’s how Comac can help you achieve your business goals:

- Comac bottling equipment

- Bottling equipment for different kind of drinks

- What to include in your bottling equipment

Comac bottling equipment

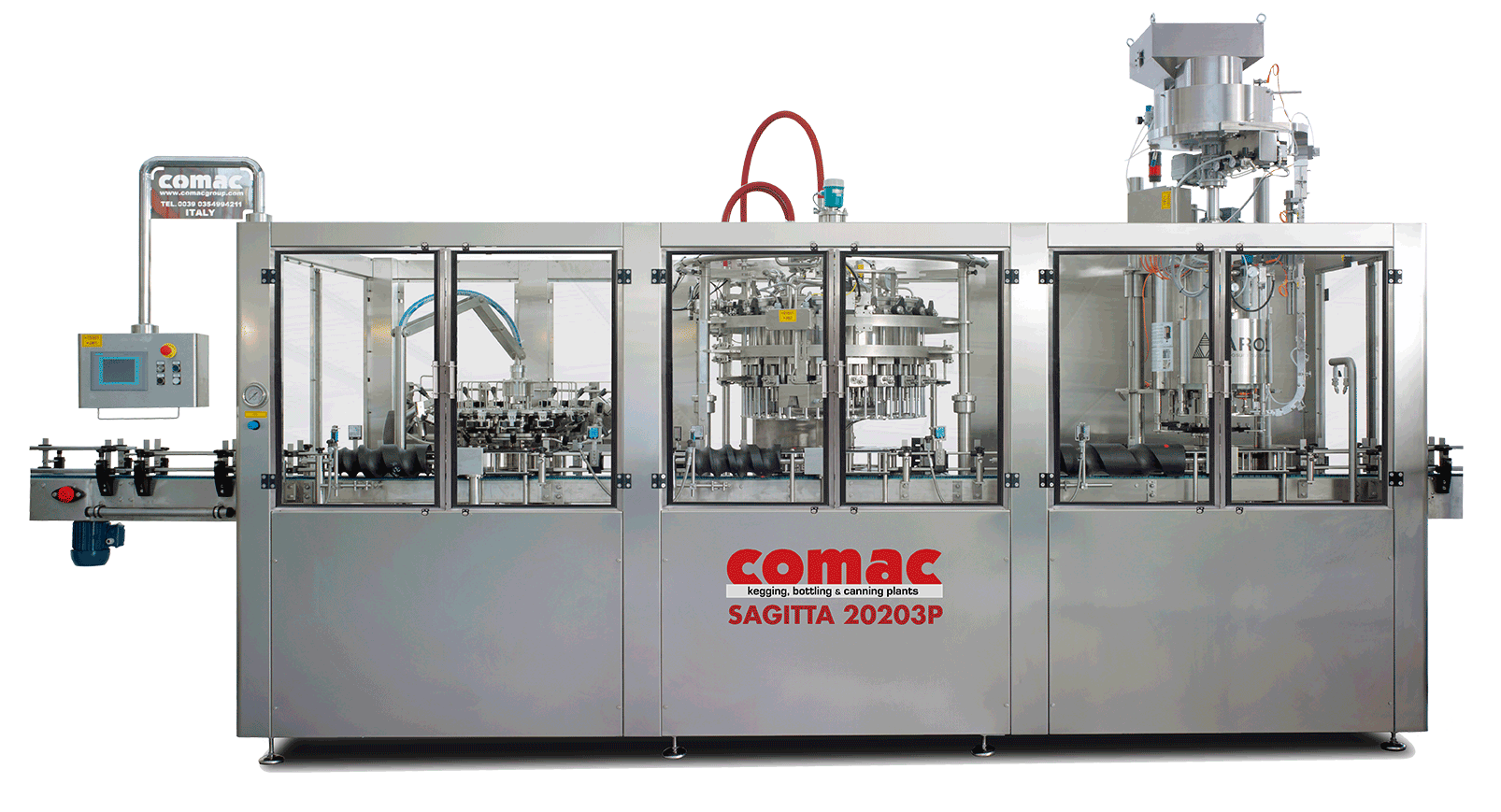

Comac boasts a twenty years’ experience in producing bottling equipment and bottle fillers for any industrial size, completely automatic and available with a high level of customization. All Comac’s machinery is made with stainless steel AISI 304, one of the most resistant and hygienic alloys employed in industrial activities. Whether you are a small business or a big industry, Comac is ready to meet your needs and provide you with the best equipment for your bottling activity.

Comac standard plants include:

Bottling equipment to process up to 3,000 bottles per hour: Sagitta 12-12-1P has been designed for small industries. This plant embodies all the technological innovation by Comac, in a compact and limited space. On request, starting from the available models, our technical staff can engineer entirely customized plants. All the plants are designed to complete the rinsing, filling and capping cycles.

Bottling equipment to process over 4.000 bottles per hour: for small and medium beverage industries, Comac offers Sagitta 12-16-3P for bottling plants with higher capacity. It offers dedicated recipes for different types of products, adjustable and selectable by HMI.

Bottling equipment to process up to 6.000 bottles per hour: Sagitta 20-20-3P has been designed for medium business and can be customized according to customers’ requests. It is based on back-pressure filling technology, suitable for filling carbonated and still beverages.

Bottling equipment to process up to 70.000 bottles per hour: for medium and big beverage industries, Comac offers Master PET, perfect for big bottling plants with very high capacity. This machine is very reliable, in fact it is able to separate air return system in order to avoid any possible contamination of the product.

Bottling equipment to process up to 80.000 bottles per hour: Master G Tech is perfect for big beverage businesses, because of its high capacity. This machine is the result of an accurate research and development and is suitable for the processing of carbonated and non-carbonated products.

Bottling equipment for different kind of drinks

Whatever your production focus is, Comac produces bottling equipment of all types and sizes. The versatility of Comac machines is represented not only by the different production capacities but also by the possibility to customize the machine according to the type of beverage treated.

For example, thanks to the oxygen pick up it is possible to remove excess oxygen to avoid product deterioration; a special measure to increase the life of bottled beverages. Thanks to these solutions, Comac is able to guarantee you a highly personalized bottle equipment to maximize your production efficiency.

The saturation unit is another component of a bottling equipment and is used for the preparation of carbonated products. It carries out all the operation of deareation and carbonation of beverages and is mostly used for water, cider and wine.

The flash pasteurizer is completely automatic and is part of a bottling equipment. It constantly checks all the working parameters and and is able to optimize time and waste production. For this reason, it is very efficient and reliable.

For bottling carbonated drinks, the precise quantities of syrup and carbon dioxide are required. Thanks to the Comac premix unit, syrup and CO2 can be adjusted and the desired combination safely achieved.

To pasteurize already packaged products it is possible to equip the bottle equipment with a tunnel pasteurizer, available in different sizes and formats.

In addition, the accessory machines also include heating and cooling tunnels to quickly change the temperature of the products, according to your needs.

Other add-ons include conveyor belts, lifts and connection elements to make the plants more functional and optimize the bottling flow.

What to include in your bottling equipment

1 – Cleaning machine

The first machine among bottling equipment should be a cleaning machine, which is necessary to perform the preliminary rinsing of the bottles before the filling process. A cleaning machine is usually equipped with a variable number of grippers – depending on its dimension – that grab the bottles and rinse them by some nozzles, through which the cleaning liquid or air is sprayed.

2 – Filling machine

The filling machine is obviously the heart of any bottling equipment. Through a conveyor, the bottles are moved under some filling valves that inject the liquid into them; sometimes, especially in beer processing, the filling machine also distributes a little amount of inert gas at the end of each filling, in order to scatter the oxygen from the top of the bottle to avoid the oxidation of the product. The best filling machines are equipped with a system to prevent the valves from working when no bottle is under them.

3 – Capping machine

The capping machine is the last device you have to provide if you want to complete your bottling equipment. After the filling, the bottles move up to this last machine, where a cap is provided for each of them, sealing the liquid and making the product ready to be stored or transported elsewhere.

4 – Additional machines

Bottling equipment could include some additional machines in case you have to perform particular processes on the beverage you are bottling. To obtain carbonated water or premix juices, you will need a saturation unit or a premix unit; a pasteurizer machine is used to pasteurize the packed bottles. There are also many other machines designed to perform specific tasks during the bottling, depending on the industry type.

Contact us if you are interested to know more about Comac bottling equipment: we will be happy to answer your questions!