Craft beer packaging: process and solutions

Craft beer, with its unique characteristics, demands professional equipment that can preserve its properties and ensure the highest standards of hygiene and safety. Discover the craft beer packaging process for bottles and cans, and see the solutions Comac offers for small breweries.

In this article, we will discuss:

- The craft beer packaging process

- Why choose a professional machine for craft beer packaging

- Comac’s craft beer packaging solutions

The craft beer packaging process

Craft beer packaging is paramount to ensuring the freshness and quality of the final product. Hence, before filling, bottles and cans need proper preparation.

This crucial process entails:

- Rinsing of bottles and cans to remove any residue or other elements that could affect beer taste and quality.

- Filling: once prepared, bottles and cans are placed on the filling valves.

- Sealing: during this final stage, bottles and cans are properly sealed to preserve the beer’s freshness and prevent the release of carbon dioxide. Bottles can be sealed with crown or pressure caps depending on the bottle and cap type. Cans are sealed through a seaming operation. This sealing process is essential for maintaining the beer quality throughout its storage and transportation to the final customer.

Why choose a professional machine for craft beer packaging

To get craft beer packaging to the next quality level, nothing compares to the efficiency of professional machinery.

Here you can find the main reasons why choosing such a solution can give your business:

- Reduced production time: professional craft beer packaging machines allow you to automate much of the process, cutting down production time considerably compared to manual packaging. This operational efficiency leads to faster market response.

- Enhanced beer quality: a machine designed specifically for craft beer packaging ensures consistent and accurate operations, avoiding human error and maintaining product quality consistently.

- Production cost saving: indeed the initial investment seems to be relevant, but in the long run, the efficiency of a professional machine for craft beer packaging can reduce waste, thus lowering overall operational costs.

- They can pack a huge amount of excellent beer effectively: these machines can handle large production volumes without compromising quality. This allows small craft breweries to expand and meet growing market demand.

- You can integrate them with other machinery: some packaging machines can be integrated with other equipment, such as pasteurizers, further optimizing the packaging process, and ensuring extended product durability and stability.

Are you still doubting the convenience of a professional machine for craft beer packaging? Comac is here to help you!

Comac’s craft beer packaging solutions

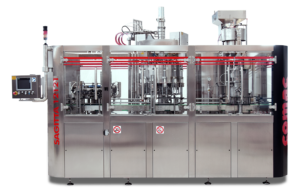

Comac, an industry leader in craft beer packaging professional machinery, offers a wide range of top-tier performance solutions. Let’s see some of those for both bottle and can packaging.

Bottle Packaging

The Sagitta 12-12-1 P model for glass bottles is ideal for packaging both still and carbonated beverages. The back-pressure filling technology ensures high-quality and accurate filling. This versatile machine has been designed to offer a complete packaging process where bottles are rinsed with water or other disinfectant solutions, filled with the desired product, and then capped. The use of electro-pneumatic filling valves makes this machine particularly suited for low and medium-capacity lines. It can produce up to 3,000 bottles per hour.

The Sagitta 12-12-1 P model for glass bottles is ideal for packaging both still and carbonated beverages. The back-pressure filling technology ensures high-quality and accurate filling. This versatile machine has been designed to offer a complete packaging process where bottles are rinsed with water or other disinfectant solutions, filled with the desired product, and then capped. The use of electro-pneumatic filling valves makes this machine particularly suited for low and medium-capacity lines. It can produce up to 3,000 bottles per hour.

The monoblock SAGITTA 12-16-3 P is a back-pressure filler for carbonated and still beverages in glass bottles. Dedicated recipes and optimal settings guarantee precise control over filling parameters. Its flexibility and customization features make it perfect for low/medium capacity lines, surpassing standard mechanical filler constraints. It boasts a production capacity of 4,000 bottles per hour.

Discover more about our bottle packaging solutions!

Can Packaging

The Microbrew 10-2 model for cans is ideal for craft beer packaging as it combines in a single bench a filler and a seamer. Thanks to electro-pneumatic valves, it provides accurate filling for still and carbonated beverages. Designed for small and medium breweries, it promises efficiency and high quality, with a capacity of 6,000 cans per hour.

The Microbrew 10-2 model for cans is ideal for craft beer packaging as it combines in a single bench a filler and a seamer. Thanks to electro-pneumatic valves, it provides accurate filling for still and carbonated beverages. Designed for small and medium breweries, it promises efficiency and high quality, with a capacity of 6,000 cans per hour.

The monoblock Microbrew 20-4 is another effective craft beer packaging solution by Comac. Compact yet powerful, it integrates a filler and a seamer in a single bench. Its back-pressure filling technology makes it suitable for still and carbonated beverages. Ideal for small and medium breweries, it ensures high performance and quality with a production capacity of 12,000 cans per hour. It features customizable settings, dedicated recipes, and consistent parameters that enhance the filling process.

Discover more about our can packaging solutions!