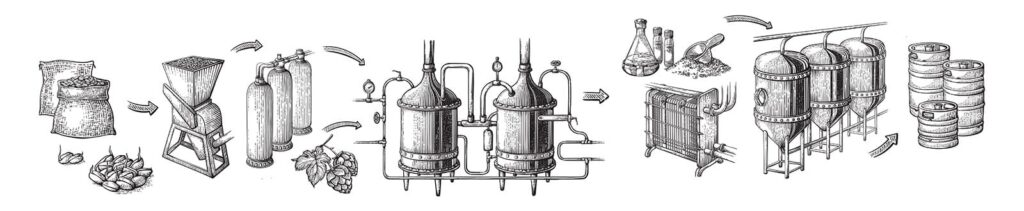

What you really need

Microbrewery is an ancient and noble activity that is becoming more and more popular as a professional business worldwide. Many people are approaching it for fun or passion, but they often get confused when the moment to choose the proper microbrewery equipment comes.

The best choice for hygiene, safety and productivity would be to choose professional microbrewery equipment, focusing on those materials that can grant resistance and quality over time. First of all, let’s see together a brief presentation of the must-have equipment for a microbrewery.

So, which is the equipment you cannot afford to miss? Discover it in this page and take a look at:

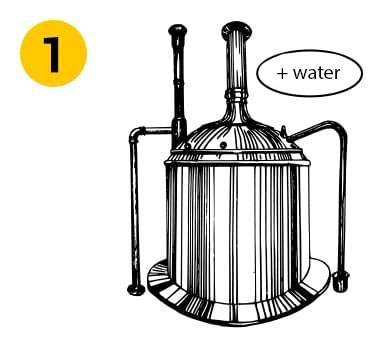

1- Mashing system

Once you have your malt milled and ready to be brewed, the first step would be to put it into a mashing system, together with water, in order to heat the mixture for the next step of the process. During this step, the malt in infusion turns into a mush of sugar.

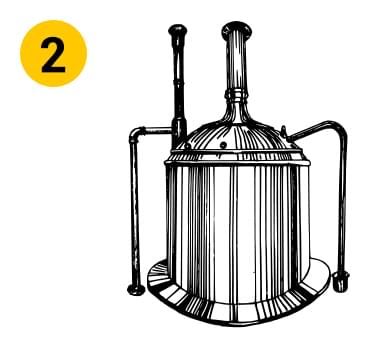

2- Lautering system

The mashing process produces a liquid rich in sugars called wort, which has to be separated from the residual grain: to this purpose, you have to use a lautering system. First, the mash must be heated again; then, it has to be “recirculated”, meaning that it has to be drawn off and put again in the mash several times; finally, the mash is trickled with water in order to extract all the remaining sugars. All of this happens in a special machine called Lauter tun, another essential component among your microbrewery equipment.

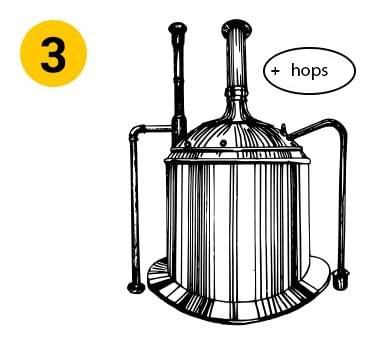

3- Brewery system

The brewery system is obviously the heart of a microbrewery equipment. The process of brewing takes place in a machine called Brew kettle, where the wort is boiled together with hops and flavors. During the boiling, the wort is sterilized, all the unwanted flavors evaporate and the solid particles are removed.

4- Cooling and fermentation

The wort is cooled down in order to bring it at the right temperature for fermentation. After the cooling, fermentation begins as yeats is put in the wort, taking place in a specific container called Fermentation Vessel. The equipment used in this step must be chosen carefully, as this is the most delicate process as far as hygiene is concerned.

5- Conditioning system

Resulting beer must be removed from the Fermentation Vessel in order to divide it from dead yeasts, which can be harmful or, at least, spoil the final flavor of the product. After that, beer is put in a conditioning system to rest and mature. This process can take few weeks as well as many months, depending on the brewer’s intent.

6- Filtering system

Filtering is essential to give the final adjustments to the flavor of the beer. However, it must be pointed out that, among the equipment of a microbrewery, a filtering system is not always necessary. Many microbreweries, in fact, sell their beer unfiltered. There are many kinds of filters, from the roughest ones, which just remove the solid components, to the finest, which eliminate all the microorganisms in the liquid.

7- Packaging system

If your Microbrewery just sells its beer where it is produced, you will not need a packaging system. But, if you want to sell the beer outside your brewery, you need to pack it into kegs, bottles or cans. A good packaging system can perform one among kegging, bottling or canning with high quality standards, speed and precision, and represents a must-have choice to complete your microbrewery equipment with all the necessary machines.

Comac’s microbrewing equipment

Comac has been producing machines and plants for breweries and microbreweries for over twenty years, earning international experience with small and big costumers all over the world. Among our products, we sell packaging equipment for microbreweries: compact and affordable plants for bottling, canning or kegging are simply perfect to complete your micro brewing equipment.

Compact size, automation, reliability: all Comac strengths made simple and easy to use.

All the machines can perform the rinsing cycle, the filling and the capping of the beer:

The automatic machines for bottling are compact monoblock units that can process up to 6,000 bottles per hour, according to your needs. Whatever the choice, you’ll have a compact machine that guarantees speed, hygiene and time-savings.

Working with cans? We have also automatic canning machines that can process up to 3.000 cans per hour.

Working with kegs? We have semi-automatic kegging systems to process between 15 and 40 kegs per hour. These models are particularly compact and easy to use, designed to perfectly fit in a micro brewery.

The difference between micro brewery and craft brewery

The volume of beer produced is the main difference between a micro brewery and a craft brewery. More precisely:

- A craft brewery is defined by the type of product it produces;

- On the other hand, a micro brewery is a small dimensions brewery (15,000 barrels of beer per year) and, even if it usually produces craft beer, it is not given for granted.

This means that craft brewery doesn’t necessarily indicate a micro brewery, and a micro brewery has to meet craft brewing standards to be considered a craft brewery.

Comac has been producing packaging systems for any kind of brewery for more than twenty years. Choose Comac’s quality to complete your Microbrewery equipment!