Complete plants and machines for the processing and packaging of beer.

We design, manufacture and install complete systems for the treatment and filling of beer in kegs (from 15 to 1,200 kph), in glass bottles (from 2,500 to over 6,000 bph) and cans (up to 12,000 cph).

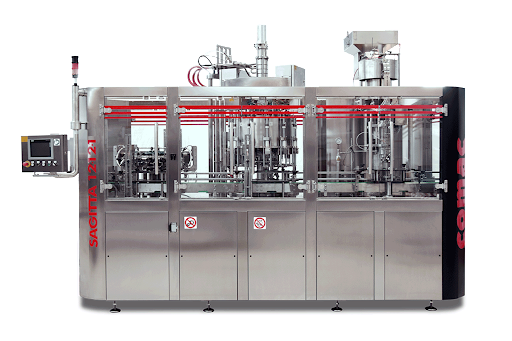

Co.Mac’s beer filling machines, semi-automatic or automatic according to production needs, can be equipped with accessory line completion machines.

Our beer filling machines

Co.Mac’s beer filling machines are divided into three lines according to the type of filling system: bottles, cans and kegs.

Bottle lines: Co.Mac offers many models of beer bottle filling machines with different dimensions and production capacities in order to satisfy the needs of a wider range of customers.

Bottle lines: Co.Mac offers many models of beer bottle filling machines with different dimensions and production capacities in order to satisfy the needs of a wider range of customers.

All our machines are automatic and can treat glass bottles of different shapes with many types of products, including beer.

Comac’s bottle filling machines are divided in two main catogories:

- Productions from 3,000 to 6,000 BPH

- Productions from 6,000 to 90,000 BPH

Can lines: Comac’s beer can filling machines are solutions designed for the treatment of cans of any size, made of aluminum, steel and tinplate.

Can lines: Comac’s beer can filling machines are solutions designed for the treatment of cans of any size, made of aluminum, steel and tinplate.

All the models are automatic and can be personalized according to customers’ requests. The high efficiency of our can filling machines depends on the high technological level and quality of the materials used for their realization.

According to their production capacity, our beer can filling machines are divided in two main categories:

- Productions from 3,000 to 12,000 CPH

- Productions from 12,000 to 70,000 CPH

Keg Lines: Co.Mac is also one of the main beer keg filling machine manufacturers, in fact we offer many solutions, all made in stainless steel, personalized according to customers’ needs.

Both semiautomatic and automatic models are available and can reach different capacity productions. Precisely, our keg filling machines are divided into three categories:

- Semiautomatic solutions able to fill from 15 to 40 KPH

- Automatic solutions able to fill from 40 to 250 KPH

- Automatic solutions for production over 250 KPH

Do you need further information about our beer filling machines?

TECHNOLOGIES RELATED TO THE PRODUCTION OF BEER

IN-DEPTH ARTICLES

Automatic bottle filling machine

We offer a wide range of automatic bottle filling machines that are capable of packaging any bottle size and type, in particular glass bottles.

Beer bottling supplies

Comac Group has been producing beer bottling supplies for more than 20 years, serving small and big breweries all over the world. On this page we are proud to introduce our solutions for bottling beer with high productivity and minimum product waste.

Beer bottling

Whether you are a microbrewery, a medium brewery or a large one, we can assist you throughout the whole beer bottling process. In fact, we deliver scaled beer bottling plants on the base of your actual needs to ensure you the utmost performance.

Beer bottling machine

Are you looking for a beer bottling machine? Comac sells automatic systems for processing and packaging beer, designed as modular units to fit the needs of both small and big breweries.

Beer canning system

Comac canning systems are plants that automatically package aluminum, steel and tinplate beer cans. There are two main types of beer canning systems, able to cover the production requirements up to 12000 cans per hour.

Beer bottle filler

Comac’s investment on research and development activities aims to solve the problems that may arise in the bottling market challenges, and has taken to the creation of new technological solutions for beer bottle fillers.

Beer canning machine

A beer canning machine increases your production capacity by cleaning, rinsing, filling and sealing several cans at one time. Whether you are a small, medium or large brewery, at Comac you will find what you need as we produce systems and plants to serve breweries of any size.

Beer bottling equipment

Comac beer bottling equipment is aimed at breweries of any size that want to bottle beer in a professional, hygienic and efficient way. To answer this need, Comac created a series of bottling machines with high quality materials, highly technological content and optimized size to offer the best solution for each specific situation.

Beer bottling line

A beer bottling line is a great investment to package your beer in a professional way. When packaged properly, beer can last much longer and its original flavor is preserved up to the moment the bottle is opened. But you probably already know that.

Beer equipment

In Comac we offer cutting edge solutions for bottling, canning and barrel packaging to be integrated to a beer equipment.

Beer kegging system

Comac Group is a leading manufacturer of beer packaging equipment for the international market. Discover our beer kegging systems for both microbreweries and big industries: affordable, professional, easy to use and maintain. Cheers!

Beer making supplies

Comac offers solutions for both Microbreweries and big Industries, with innovative plants to cover the kegging, bottling or canning, all the three of them at the highest standard of quality available on the International market.

Beer packaging

Beer packaging is an extremely important process in the production and sale of this beverage. We all know that beer can be packed inside bottles, cans or kegs, each with its pros and cons. On this page we will deepen the reasons to choose one or another kind of packaging among bottling, canning or kegging.

Beer pasteurizer

Despite the fact that beer is naturally free from pathogens and contaminants dangerous for human health, pasteurizing it is the best method to prevent taste degradation and extend shelf life of packaged beer. So, if it has to be shipped and sold outside your brewery, the beer would better be pasteurized.

Microbrewery equipment

Microbrewery is an ancient and noble activity that is becoming more and more popular as a professional business worldwide. Many people are approaching it for fun or passion, but they often get confused when the moment to choose the proper microbrewery equipment comes.

Bottling beer equipment

Comac has a wide range of choice when it comes to plants and machines, ranging from the automated plants for cleaning, filling and capping bottles to the coolers and saturators. The company supplies customers from all corners of the world: in Americas, Africa, Asia and the rest of Europe.

Micro brewing equipment

Micro brewing is a becoming all over the world more and more popular as a professional activity. However, many microbreweries still underestimate the importance of using professional micro brewing equipment to make beer, as a choice of quality and safety.

Keg washer

A keg washer is an essential machine to guarantee the best parameters of hygiene and safety to the beverage you are storing into kegs. Washing the kegs, in fact, is a process that eliminates all the dangerous agents inside and outside, preventing the contamination of the product during the keg filling process.

Bottle filler

The production of bottle filler plants and machines has always been the core activity of Comac’s business. For more than twenty years, Comac has been researching, developing and creating cutting-edge bottle fillers for any use and any customer, placing as one the world leaders in bottle packaging systems.

Bottle packaging

The production of plants and machines for bottle packaging is one the activity in which Comac can boast its longest and best experience. This page is dedicated to present the best solutions for bottle packaging proposed by the Italian worldwide-renowned business.

Bottle equipment

What bottle equipment do you need? It depends on many factors, including the space available, the capacity and number of bottles you want to fill, as well as the type of drink you need to bottle. Comac’s bottle equipment is easy to use and guarantees maximum reliability without the need for frequent maintenance.

Bottling equipment

Bottling equipment includes a series of machines or plants realized to process the filling of bottles in beverage industries. It does not matter what size your business is: the bottling process always requires some necessary steps, each of them with a specific machine to perform it.

Bottling plants

Are you looking for a bottling plant for your business? Welcome on the page dedicated to the products by Comac, specifically designed to perform the bottling for small, medium or big industries that work in the beverage field.

Bottle filling lines

From rinsing to capping, Comac’s bottle filling lines are much more than basic filling machines. Discover all their features and benefits. Comac machines are ideal solution for the bottling of: beer; water; soft drinks; alcoholic beverages.

Beer plants

Comac produces complete plants and machines for processing and packaging the beer in bottles, cans or kegs. The wide range of available machines allows the study of personalized systems that can meet the requests of small, medium and large producers.

Bottling System

Choosing a bottling system realized by Comac means choosing the best way to process and pack all types of beverages, both alcoholic and no alcoholic. A Comac bottling system is able to realize the complete process of beverage treatment: rinsing, filling and capping of bottles.

Beer filling machines maintenance

Comac provides complete plants and machinery for beer processing and packaging. Here’s our tips to maintain our filling machines at their best.

Alcoholic Beverage

Comac produces complete plants and machines for processing and packaging fermented, distilled or liqueur alcoholic beverages in bottles or cans.

Bottle filling machines

Which is the best bottle filling machine available on the market? Discover Comac’s models and find the perfect solution for your company.

Beer can filler machine

Comac produces beer can filler machines which can handle different sizes and formats, while keeping an incredibly high productivity. Read our insight and discover more.

Automatic beer filler

Discover our automatic beer filler machines: fast and reliable, they can produce bottles, cans and kegs.

Beer keg washing machine

Maintaining hygiene in the beer production process is crucial, especially regarding kegging. Explore on this page the importance of beer keg washing machines, the top products from Co.Mac, and why you should rely on our expertise for your keg washing needs.