Sustainable beer packaging: advantages and solutions

In the brewing industry, sustainable beer packaging has become crucial in reducing environmental impact and improving brand image. Breweries can help protect the planet by adopting eco-friendly packaging solutions while gaining competitive advantages. Discover how Co.Mac solutions can help achieve this goal.

In this article:

- Why focus on sustainable packaging today

- Types of sustainable packaging for beer

- Co.Mac equipment for sustainable packaging

Why focus on sustainable packaging today

Sustainable packaging is now a priority when complying with stricter environmental regulations and meeting consumers’ growing ecological concerns.

The UN’s Goal 12 for the 2030 Agenda, named “Responsible consumption and production,” urges businesses to innovate and reduce environmental impact maximizing resources and improving process efficiency.

The beverage industry, particularly beer, is well-positioned in achieving these objectives. Implementing sustainable beer packaging allows breweries to significantly reduce waste, save energy, and minimize the use of non-recyclable materials like traditional plastic.

Moreover, adopting eco-friendly practices can save long-term costs by reducing waste and improving operational efficiency.

This sustainable approach not only protects the environment but also increases consumer trust and loyalty, as customers are more likely to support brands that demonstrate a commitment to sustainability. In so doing, breweries can contribute to a greener future, while strengthening their brand image, which can lead to a significant competitive advantage on the market.

Types of sustainable packaging for beer

Sustainable beer packaging relies on eco-friendly materials that help reduce environmental impact.

For breweries looking to combine sustainability and cost-effectiveness, the use of stainless-steel kegs, recyclable plastic kegs, aluminum cans, and glass bottles offers an ideal solution for eco-responsible and efficient packaging:

- Kegs are a perfect solution for beer packaging, especially for large-scale distribution. Stainless steel kegs can be reused many times, reducing the need for new materials while minimizing waste. Recyclable plastic kegs offer a lightweight and ease-of- transport alternative without compromising sustainability.

- Aluminum cans are valued for their lightweight nature and ability to be infinitely recycled without losing their original properties. This continuous recycling process significantly reduces environmental impact, as it requires less energy than producing new materials. Additionally, their lightweight nature reduces transportation costs and the associated carbon footprint.

Read also: Beer can packaging: why choose it?

- Glass bottles are the most traditional solution and are also completely recyclable and reusable. They preserve the quality and flavor of the beer just as effectively as cans.

Co.Mac equipment for sustainable packaging

Among the beverage companies prioritizing sustainability in their processes and products, Co.Mac stands out for its innovative machinery designed for sustainable beer packaging, focusing on energy efficiency and waste minimization.

Co.Mac automatic filling lines for kegs, cans, and bottles are designed to optimize resource usage while maintaining high standards of quality and productivity.

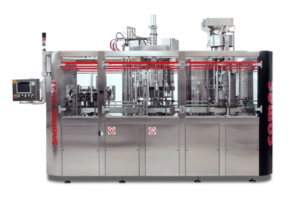

Image: Bergamo (300 kegs/hour), Microbrew 20-4 (12,000 cans/hour), and Sagitta 12-12-1 P (3,000 bottles/hour)

These machines significantly reduce product waste during the filling process and consume less energy, promoting more eco-friendly production.

Customizing production lines according to customer requirements also allows breweries to improve operational efficiency, reduce environmental impact, and ensure greater long-term sustainability.

Find out how we can help improve the sustainability of your production and brand.

Choose our sustainable beer packaging solutions

and make your production more efficient and responsible.